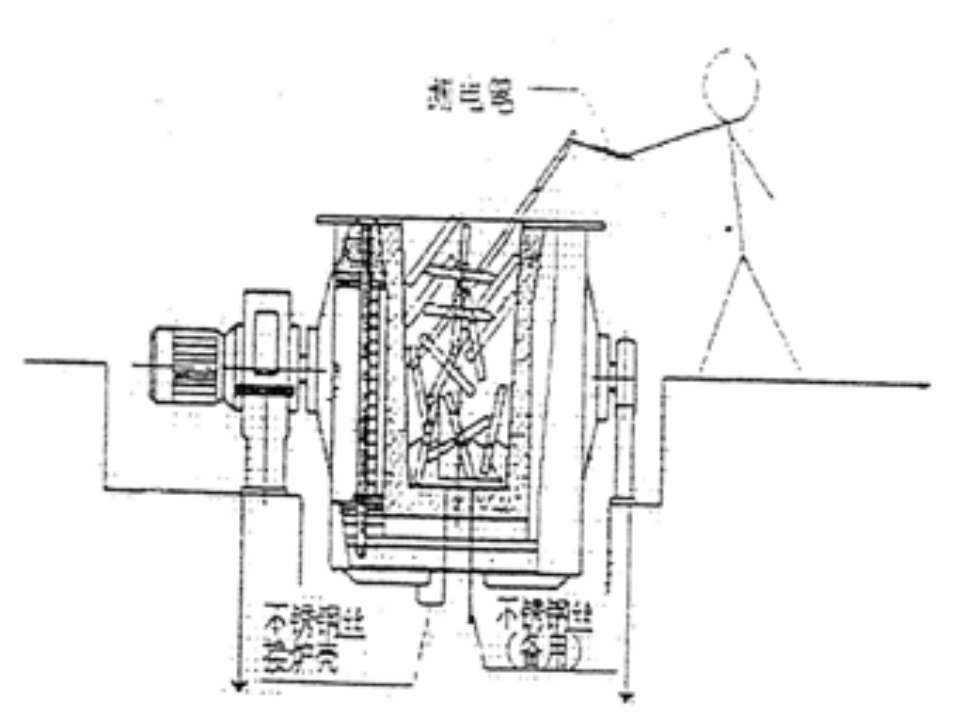

01. The installation foundation of the induction furnace must meet the installation size requirements, and the furnace surface should be kept horizontal during installation.

02. The installation of the waterway must be firm and correct, and the distance between the water-cooled cable and the steel pipe used for the waterway should be greater than 50cm.

03. After the furnace body is installed, a tilting test must be done, and the furnace body should be tilted from 0 to 95 degrees. It is required to move smoothly, rotate flexibly, and stop the furnace accurately.

04. The power cabinet, furnace body and outer casing have safety grounding and protective grounding. The three-phase incoming line and neutral line in the cabinet must be connected firmly.

05. There is a backup water source (water tower or uninterrupted tap water) or emergency use when the backup power supply is out of power. The water flow of the backup water source for cooling the furnace body is greater than or equal to 5T/h, and the return water is made of steel water pipes or trenches.

06. There is a spare water pump to prevent the main pump from being damaged. The standby pump, main pump, power supply cabinet, furnace, water cable, and the main water circuit of each branch of the capacitor are controlled by valves, so that they can be adjusted and used in various situations.

07. The room where the cooling tower, furnace body, power supply cabinet, and capacitor cabinet are placed shall have ventilation and exhaust, lighting, and drainage facilities.

08. The cable trench must be covered with a wooden or cement cover. Cooling towers, furnaces, power cabinets, and capacitor cabinets must be bright and easily accessible.

09. There are observation windows in the operating room of the power cabinet and the wall in front of the furnace.

01. The operator in front of the furnace must have certain electrical knowledge, and take up the job after passing the training. Work strictly in accordance with the operating procedures; warning signs must be set up on live parts. Equipment management personnel shall conduct safety education for employees before class; equipment safety must be checked regularly.

02. Staff must wear protective equipment such as insulating shoes, insulating gloves, goggles and safety helmets. , and stand on a dry insulating board (the thickness of the insulating board is more than 20 mm and the withstand voltage is more than 10,000 volts). Lay 3cm thick dry wood in front of the power cabinet.

03. Non-stove operators are strictly prohibited from operating on the stove and entering the electrical room to stay.

04. It is necessary to ensure that the furnace table, safety pit, and the lower part of the furnace are clean and dry, and there are no sundries around the furnace to prevent short circuits.

05. It is strictly forbidden to use unqualified refractory charge to tie the furnace lining.

06. During the feeding operation, the cold and wet charge should be dried first, and cannot be directly thrown into the solution. Flammable, explosive, and sealing parts are strictly prohibited from being placed in the furnace, so as not to cause the furnace to explode and the solution to spray.

07. When working, it is strictly forbidden for the human body to directly touch the furnace shell and furnace cover.

08. Use a full-time electrician in the work, and use a test pen every 10 furnaces to test the metal charge and furnace shell, and they cannot be charged.

09. (1) During the work, it is found that the metal material in the furnace has the phenomenon of sparking and arcing on the furnace cover. The furnace should be stopped immediately (at this time, the furnace lining has leaked electricity, and strong voltage enters the furnace, which will endanger personal safety).

(2) If it is found that the ground wire in the furnace is open or blown. When it is blown after being connected, the furnace should be stopped immediately (the furnace lining has been charged with strong voltage and cannot be used again).

(3) During the opening of the furnace, the situation in the furnace should be observed frequently to prevent the occurrence of molten steel freezing, sealing and overheating. The freezing and sealing time of the charge on the upper part of the furnace body should not be too long, so as not to cause a furnace explosion accident. When the phenomenon of freezing and sealing is found, the furnace should be dumped to a certain angle in time to melt the frozen part of the charge. If the electric furnace is frozen and sealed within 10 minutes, it should be stopped immediately.

10. Disconnect the air switch before overhauling. When overhauling the capacitor cabinet, the capacitor must be discharged.

Before the operation, you must familiarize yourself with the electric furnace safety operation specifications provided by our company. All operations must follow the safety operation specifications to ensure that the machine has been installed correctly and has been debugged. Make sure not to let anyone touch the control panel indiscriminately.

1. Preparation before the furnace is opened

1) Check whether the fasteners in each part are loose;

2) Check whether the insulation of the main power supply in the cabinet is good;

3) Check whether the water pressure, flow and water temperature of each waterway are normal;

4) Check whether the working indication on the "central control panel" is normal;

5) Check whether the trigger pulse (rectification, inverter) indicator light is normal;

6) Check whether the insulation of the induction coil and capacitor of the furnace body is normal to the ground;

7) Check whether the water cooling cable is in reliable contact;

8) Check whether the incoming line voltage is normal

The above items can start the IF power supply under normal circumstances.

2. Intermediate frequency power supply operation

2.1. Start operation

(1) Start the water pump to supply water to the cooling system;

(2) Close the circuit breaker Q1 of the control circuit in the cabinet to supply power to the secondary circuit (if it is a multi-pulse intermediate frequency electric furnace, close the circuit breakers of each control circuit in turn);

(3) Press the "Control Power On" button to control the power supply;

(4) Press the "Main Power On" button, the main circuit is powered;

(5) Turn the "Reset" button to the right to prepare for the start of the intermediate frequency power supply;

(6) Slowly adjust the "power adjustment" potentiometer PR and pay attention to the frequency meter. If there is an indication and you can hear an intermediate frequency sound, it means that the startup is successful. After the startup is successful, turn the potentiometer PR to the end once, and the main control The "Start P.P" light on the board is off, and the "Voltage Loop V.LOP" light is on. If the startup is unsuccessful, it needs to be restarted;

2.2. Stop the operation

(1) Rotate the power adjustment potentiometer PR counterclockwise to the end, and all indicating instruments return to zero.

(2) Press the "main gate open" button, the main circuit is powered off;

(3) Press the "Control Power Point" button, the control power is cut off;

(4) Disconnect the circuit breaker Q1 of the cabinet control circuit (if it is a multi-pulse intermediate frequency electric furnace, disconnect the circuit breakers of each control circuit in turn);

3. Other instructions

1) When a fault occurs, the "central control panel" can keep memory, and the power can be restarted only after the fault is eliminated and the "reset" button of the intermediate frequency is pressed;

6) When a fault or emergency occurs, the power supply should be stopped according to the power-off procedure, and the power supply can be restarted after the fault is eliminated;

7) The stop time of the water pump should be determined according to the water temperature in the sensor. Generally, the water supply should be stopped about 240 minutes after the power supply is stopped, and the cooling water of the power supply can be stopped immediately;

01. Operate the equipment in strict accordance with the regulations. It is strictly forbidden to open the equipment when the load is open. The water-cooled cable cannot be opened, otherwise the components will be damaged. The water-cooled cable connection bolts should be tightened, and the copper bars should be checked for foreign objects.

02. When the cold furnace is fully loaded (starting with a crucible or starting after the molten steel solidifies due to a power failure), low power operation (full power 30%) until the steel is melted to 30% of the full capacity, and then gradually increase the full power until the whole furnace is melted. During the process, the furnace body is constantly flipped back and forth at a small angle at certain intervals.

03. The molten material should be grounded to ensure personal safety. The specific method is as follows:

Instructions: 1) During the feeding process, use a test pen to measure whether the furnace is electrified or not. If it is electrified, it is strictly forbidden to operate.

2) The furnace shell should be grounded reliably.

3), insert two bundles of 2mm stainless steel wires into the bottom of the furnace, one for the outer shell and one for spare.

04. Matters needing attention after furnace lining sintering:

(1) After sintering, the first 3-5 furnaces are melted, and it should be operated at 60%-70% of the rated voltage (mainly to protect the coil insulation); when the furnace is stopped for more than 5 days, it is necessary to use 1/10 of the Power on for more than 20 minutes.

(2) It is best to disable iron filings in the first furnace, and it is strictly forbidden to add sealed tubular materials and wet materials.

05. The service life of the furnace lining is related to continuous smelting or intermittent smelting. Generally speaking, the continuous smelting furnace has a long service life, while the intermittent smelting has a short service life. Therefore, the furnace block should be placed in the furnace before the furnace is shut down, which can achieve the purpose of slow cooling and prolonging the life of the furnace. Always check the lining condition.

07. The inlet water temperature is 5-35°C (water below 5°C should not be used to prevent the pipeline from freezing and cracking). Note: The inlet water temperature of the cooling system should be higher than the dew point to prevent moisture from condensing on the sensor, causing insulation breakdown of the sensor and short circuit between turns. The outlet water temperature of the intermediate frequency power supply is generally lower than 45°C, and the outlet water temperature of the sensor is lower than 55°C

08. The cooling water flow rate should be maintained at 1-1.5 m/s. Note: The water flow should be turbulent

09. The cooling water inlet pressure is 0.2MPa-0.3MPa for the frequency conversion device and 0.3MPa-0.35MPa for the furnace body

Note: If the water is stopped for more than 20 minutes during the operation of the furnace, the insulation of the sensor may be burned out. Therefore, in addition to being on duty day and night to monitor the work of the water cooling system, an emergency water tank should be set up to continue supplying water to the furnace in the event of a power outage. After the furnace is stopped, reduce the water flow and continue to pass water for more than 4 hours to ensure that the furnace lining is cooled to the allowable temperature<100>

10. Provide water as soon as possible during a power outage, otherwise steam will be generated in the coil tube and cause an explosion. Start the emergency water source, and control the water flow to 1/3 of the water volume during smelting.

11. The outer surface of the inductor coil and cooling water pipe should be blown clean with compressed air regularly.

12. For use in summer, if the cooling water temperature is too low to cause condensation droplets on the surface of the components in the cabinet, the temperature of the cooling water inlet should be increased to prevent condensation from entering the system, resulting in reduced insulation and system damage. Frequently check whether there is sediment in the reinforcement pipe in the cabinet.

13. If the furnace is shut down for a long time in winter, the cooling tower treatment method: 1. Dry the water in each water pipe with compressed air to prevent the pipes and electrical components from freezing and cracking; 2. It can also keep the water circulation uninterrupted (ie the water pump 3. Or you can inject antifreeze into the cooling water to ensure that the cooling water will not freeze at low temperatures.

14. The power distribution worker should always observe the operation of the equipment, make a careful record of the power distribution, and call an electrician for repair immediately if there is a problem. It is not allowed to change the load with electricity, pull the gate with load, and do not tilt the furnace body with load.

15. Check the working condition of the water tank regularly and irregularly, there is no blockage, no leakage, and the water temperature is normal. If there is any abnormality, stop the power transmission and check.

16. Pay attention to the various phenomena that occur in the work and the reading records of the instrument at regular intervals. The power knob is not at the zero position and the reset button cannot be pressed.

17. During operation, the yoke of the furnace body should be checked frequently to observe whether there is redness. If there is, the furnace should be stopped immediately to check the waterway of the corresponding part. If the furnace body bracket, induction coil, magnetic yoke, power supply, water cable joint and capacitor cabinet are found to be on fire during operation, the furnace should be stopped immediately and the relevant leaders should be reported.

18. Regularly check the furnace tilting device and water cooling switch, and add lubricating oil frequently. Regularly check the grounding wire connection, the grounding wire must be firmly connected.

19. All the screws in the power cabinet, the fastening bolts of the furnace body structure and the fastening bolts of the inductor coil should be fastened regularly.

20. After the furnace is shut down after get off work, conduct a comprehensive inspection of the equipment, pay attention to the heating of each part, the resistance and capacitance of the key part of the inverter thyristor is absorbed back to the original device, etc., whether there is any phenomenon such as burnout and poor contact, and if there is any problem, it will be timely. solve. The handover needs to do a good job of site sanitation. Before leaving get off work, dehydrated compressed air should be used to carefully blow off the dust in the furnace body and electric cabinet, and handover records must be made for various unsafe factors and equipment failures.

21. Emergency shutdown and report to professionals in the following situations:

1). Severe shedding and cavities occurred in the furnace lining.

2). The intermediate frequency voltage drops and the AC current rises sharply.

3). Water temperatures generally rose sharply.

4). Leakage alarm alarm and reset several times can not be eliminated.

22. When dismantling the furnace, attention should be paid to the safety of the griddle to prevent collapse and injury. There must be someone to supervise it, and at the same time be careful not to damage the coil. .

23. During the period of starting the furnace and pouring the metal solution, stop the furnace and release it. And do not stack debris around the stove. The sundries fell and got on the induction coil, causing a short circuit.

24. When dismantling the furnace lining, care should be taken not to damage the coil cement. If there is damage and burning cracks, the damaged parts should be removed, repainted, and the furnace lining should be built after natural solidification and drying.