The use state of the furnace lining has the most direct relationship with the furnace building. Let's talk about the problems often encountered when building the furnace according to our furnace building sequence.

(1) Repair of insulating paint on coil surface

At present, the insulation treatment of the electric furnace coil plays a crucial role in the production safety and efficiency improvement of the entire electric furnace. If the insulation treatment is not good, the intuitive phenomenon is that the coil will have obvious ignition or arcing phenomenon, serious and direct breakdown. Copper tubes can cause production safety accidents, and it is easy to burn the intermediate frequency power supply, or cause the phenomenon that the furnace power cannot be increased.

Before each furnace lining, especially before redoing the coil slurry, it is best to conduct the overall surface insulation treatment of the coil. Bare leaked clean copper surface, and then spray the insulating paint. Since the electric furnace is operated at high temperature, even if there is water cooling in the copper tube, it is easy to win the failure and cause the local temperature map to be too high, which is the phenomenon of carbonization of the insulating paint. Therefore, it is recommended to mainly use TSC-L ultra-high temperature insulating paint to ensure that it is 750 It will not be carbonized below ℃, thus fully guaranteeing good insulation performance.

(2) Repair of coil paste

In the use of electric furnaces, due to the long-term dismantling, installation and recycling of the furnace lining, our electric furnace coil slurry will be damaged to varying degrees. For electric furnaces, this layer of coil slurry is the last layer to protect the coil in addition to the ultra-high temperature insulating paint on the surface. A barrier, if the damage is not repaired in time, the probability of damage to the coil will increase, which will also affect the safety factor in our production. Therefore, it is very necessary to repair the coil slurry before each furnace construction. Before repairing The first thing is to clean the dust on the damaged surface. After making sure that there is no quartz sand or other materials left by the last furnace lining around the exposed coil, mix the coil slurry with a proper amount of water and evenly coat the damaged area. The thickness should be Keep the same as the intact coil slurry and on the same arc surface. After repairing work, if the damaged surface is relatively large, the moisture in the material must be dried first, and then the furnace building operation is carried out. If it is relatively small, you can wait for a period of time to let it cure and dry by itself before lining construction.

(3) Installation of alarm line

When installing the leakage furnace alarm line, ensure that each alarm line is separated by a certain distance (5--10 cm) inside the electric furnace. This is to reduce the heat accumulation of the alarm line and prevent the alarm line from melting and causing the furnace bottom. The phenomenon of molten iron leakage occurs. Before the construction of the furnace bottom, the fixed alarm line should be pressed on the alarm line with a piece of asbestos plate or asbestos cloth with an area of about 30*30CM, because the fixed alarm line is often under the action of tension or in the There are different degrees of warping during the charging construction process, and after pressing, it will make it close to the bottom of the furnace to push out the block. The purpose of this is to ensure the standardization of the design thickness of the furnace bottom and the design capacity of the electric furnace, and also to ensure that the The stability of the alarm line during the construction of the furnace bottom. When fixing the alarm line outside the electric furnace, the insulation between the alarm line and the furnace body should be considered. Gasket, this is to prevent the ground wire connected to the alarm wire from falling off during the production process, which will cause the operator to form a series connection with the molten iron in the furnace and the furnace body during the melting process and cause electric shock. After connecting the alarm wire, it should be Confirm whether the alarm line is connected, and then proceed to the next step.

In addition, the latest generation of CPAS coil protection and furnace leakage alarm system has a better protective effect on the intermediate frequency furnace, and can monitor the thickness change of the furnace lining at various positions online very intuitively, and it is installed inside the slurry layer, with longer life and maintenance. More convenient, is the future trend of intermediate frequency furnace floor furnace alarm.

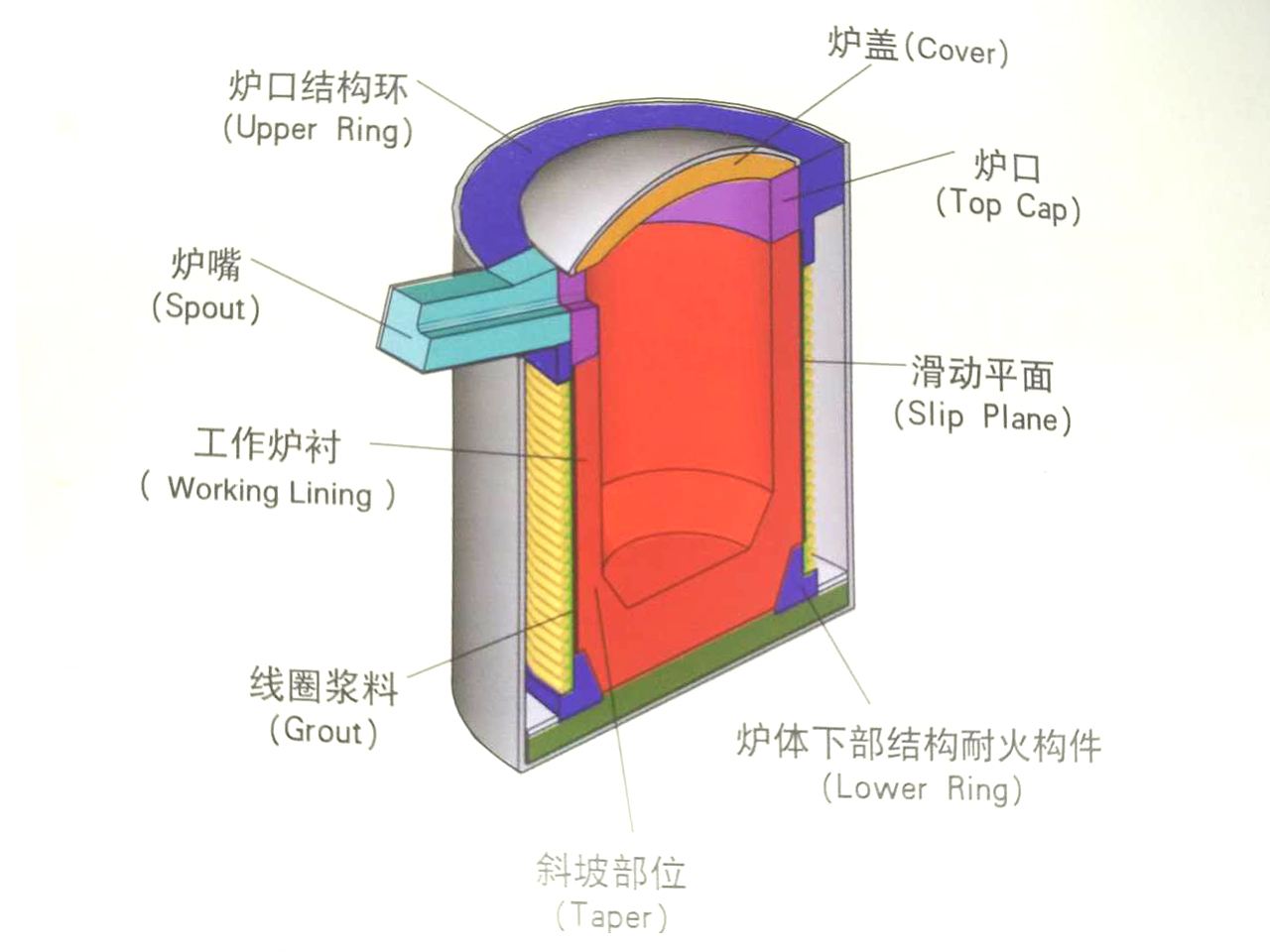

(4) Installation of backing

In order to make it easier to dismantle and push out the furnace lining that needs to be re-constructed, we generally use a spare lining, also called a sliding plane layer. Using the spare lining can save effort to remove the furnace lining that needs to be re-constructed, and at the same time, it can also protect the coil slurry. The role of the material, we now use asbestos cloth as a backing, asbestos cloth has always had its inevitable shortcomings in using as a backing, the first is the impact of its asbestos composition on human health, because asbestos fibers are inhaled into the lungs by the human body. It is difficult to be excreted from the body, and in severe cases, it will cause carcinogenicity, so everyone should be equipped with the labor protection supplies distributed by the company when doing any work at work. Second, the toughness of the asbestos cloth is not enough. We often accidentally touch the asbestos cloth during the construction of the furnace bottom and furnace lining, which causes the asbestos cloth to be damaged, which brings us a lot of trouble. Treatment may have problems affecting the safety of the furnace lining. Another point is the problem of its thermal conductivity. Asbestos itself is a kind of thermal insulation object. In the use of our furnace lining, the furnace lining has always had a relatively clear temperature gradient. Due to the poor thermal conductivity of asbestos cloth and its excessive thickness, etc. The reason will affect the heat loss effect of the furnace lining and reduce the thickness of the loose layer of the furnace lining, which brings certain safety hazards to our production and use process. Due to the above shortcomings of asbestos cloth, some foundries are now using mica paper to replace asbestos cloth. Mica paper has good toughness, and its thickness is only 0.32 mm, which will not affect the temperature gradient of the furnace lining at all. In addition, due to the gas impermeability of mica paper, the number of false alarms caused by moisture in the furnace lining during the sintering process can be greatly reduced. These advantages make mica paper quickly and widely used as a backup lining. Before laying the equipment lining, it should be prepared in advance according to the size and height of the electric furnace. When laying, first remove the material left on the furnace wall last time, and then lay it after cleaning. When laying, one person should go down to the inside of the furnace, and the other person should stand in the furnace. Put down the prepared lining vertically on the top, and the length is 10-20CM beyond the top of the furnace. Then the staff in the furnace is responsible for smoothing it so that it is close to the furnace wall, and then put the second prepared lining. The second piece of lining should be overlapped with the first piece by about 10CM to prevent the lining from being punched out when the furnace lining is added.

The first thing to do in the construction of the furnace nozzle is to clean the material contact surface at the furnace nozzle, and then use the plastic material to make the geometric figure of the furnace nozzle, and make fine holes on it (the purpose is to discharge the plastic material smoothly during the drying process). water vapor, otherwise it will cause cracking and damage of the furnace nozzle), when constructing the contact surface between the furnace nozzle and the furnace lining material, it is necessary to ensure that the furnace nozzle material and the coil slurry are on a vertical plane, and maintain the same arc, the furnace nozzle material It must not be overlapped on the furnace lining, because the furnace lining has a certain degree of shrinkage and expansion when the furnace is cold and fired. The overlapping of the two materials will increase the gap between them, resulting in the phenomenon of iron sticking. After the furnace nozzle is constructed After drying, it is necessary to carry out the furnace lining operation after drying, because the plastic material will have 1%-2% shrinkage after drying, and the furnace lining operation after drying can better maintain the tightness between the furnace lining and the furnace lining. It can reduce the probability of iron infiltration between the plastic material and the furnace lining.

In the initial charging of the furnace bottom construction, someone must carry out the charging operation in the furnace. This is to better arrange the prepared lining more smoothly, so that the prepared lining will not affect the furnace lining to achieve better results. The bottom of the furnace is the first You can add more for the second feeding (the first feeding can be 10CM, and then control it at about 5-8CM each time). If too little is added, the exhaust fork directly touches the bottom push-out block, and the exhaust effect will not be achieved. After the material is good, it must be leveled first, and then exhausted 4-6 times. After the exhaust work is completed, the surface of the quartz sand must be shaved before the second feeding. This can avoid the occurrence of different levels of feeding. Layering phenomenon. When carrying out the exhaust work, pay attention to the exhaust at the position between the alarm line and the line and do not neglect it. If the alarm line is bent during the construction process, it should be restored to its original state immediately, and then the exhaust operation should be carried out. It is best to increase the charging height of the furnace bottom to a height of 10CM higher than the alarm line, because there will be a certain falling space when the furnace bottom is shaking. If there is not enough falling space, the alarm line will directly top during the shaking process. On the plate vibrator, it is possible that the density of the quartz sand at the bottom of the furnace does not meet the standard, and the normal service life cannot be achieved due to excessive erosion during production and use. After the furnace bottom construction is completed, find at least 1-2 alarm lines and scrape off the floating material layer on the surface of the alarm line in the horizontal direction, and then use a spirit level to level the furnace bottom material. After the bottom of the furnace is vibrated and compacted by the flat bottom, attention should be paid to the lining condition. When the lining is damaged, the damaged surface should be cleaned up in time and the next step of construction can be carried out after ensuring that no damaged lining materials are mixed in the furnace lining.

The design of the crucible is to allow the water in the furnace lining to be discharged better and faster. The surface of the crucible will be drilled with a 3-5MM hole every 25CM. The surface of the crucible mold should be cleaned before putting it into the furnace. , and then seal the pores with adhesive tape. The purpose of this is to keep the surface free of rust or dust, so as to ensure that no debris enters the quartz sand and affects the sintering effect of the furnace lining. In addition, the sealed pores can prevent The phenomenon of material running occurs during the shaking operation. When the crucible is placed in the furnace, we must ensure the principle of "one level, two positive, three-phase, etc.". "One level" means that the crucible should be stable after being placed in the furnace, and there should be no large-scale shaking to prevent the furnace lining. Or the crucible shifts during exhaust work. "Second positive" means that the crucible cannot be tilted after it is put in, and it is necessary to ensure that the crucible is on a vertical line up and down. "Three-phase equal" means that the position of the crucible must be in the middle position, and it is necessary to ensure that the distance from each point of the crucible wall to the coil is equal, so that the thickness of the furnace lining can be consistent in the future. These points are very important, because the correct position of the crucible directly affects the service life of the furnace lining. After placing the crucible, there is another important step, which is to scrape the quartz sand on the bottom plane of the crucible before adding the furnace lining, because the current bottom of the furnace has a high density after being vibrated, and it is difficult to scrape. To reach the required depth, we can first use the exhaust fork to forcefully insert the furnace bottom material loose, and then shave the hair. The purpose of this is to avoid the delamination phenomenon that is easy to occur in this part.

When lining the furnace, due to the design of the crucible and the needs of the furnace, there will be a slope in the furnace lining part. This position is directly related to the service life of the furnace lining. When constructing the slope position, the key point is to pay attention to the exhaust work of quartz sand at this position. , Since the lining material at the slope position is not vertical, the lining material at this position cannot completely rely on its own gravity to increase the density of the material when the vibration is used. Generally, the construction is carried out with less feeding and more exhausting. The height of each feeding in this position should be kept at 5-6CM. First level and then exhaust 6-8 times. After exhausting, shave and then For the second feeding, after the construction site exceeds the slope, the thickness of the feeding can be increased, but it should also be kept within 10CM. The whole furnace lining construction must be carefully and carefully. After each charging work, a flashlight and other lighting tools should be used to observe the charging situation, and it should be confirmed that the backup lining has not been punched out by the charging material, and whether there is any foreign matter entering the charging material. After each exhaust, it should also be confirmed whether the lining is complete and whether there is any damage. After the whole furnace lining is charged, the crucible is fixed by electric welding, which can prevent the crucible from shifting during the shaking operation. A part of the charge should be reserved before the shaking operation to replenish the lining material dropped during the shaking process in time. It is best to use sealing material in this position if conditions permit. Since we use pneumatic Martin to vibrate the furnace lining, it is generally required that the air pressure should be at least 0.42Mpa, and then the vibration should be more than 3 minutes. If the air pressure is not high enough, the vibration time can be appropriately extended, and the furnace lining must have a sufficient density. At the same time, attention should be paid to the fixing of Martin during the vibration. If there is any loosening, the air pressure should be turned off immediately, and then the vibration should be carried out after tightening.